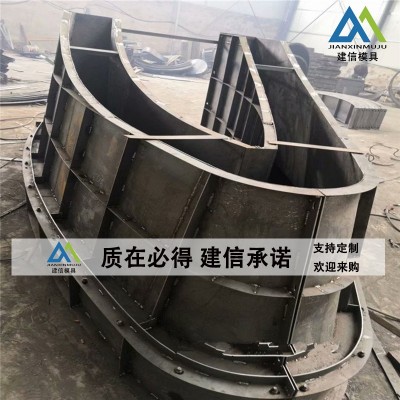

混凝土隔离墩模具设计是在满足客人的需求的前提下,加工成本低,加工难度小,处理时间短。要做到这一点,不仅要充分理解客户的需求,在注塑机,水泥隔离墩模具结构,加工工艺和模具工厂的能力等等。

The mold design of the concrete isolation pier is based on the premise of meeting the needs of the guests, the processing cost is low, the processing difficulty is small, the processing time is short. To do this, not only need to fully understand the needs of customers, in the injection molding machine, cement block mold structure, processing technology and mold factory capacity, and so on.

因此,为了提高混凝土隔离墩模具设计水平,应该做到以下几点,首先理解每个模具设计细节,了解模具的每一部分;其次一个类似的设计,在设计时参考和理解其他模具加工和生产的产品,吸收经验和教训;再者更多地了解注塑机的工作过程,深化模具;后理解、处理和产品过程中知道每个进程。知道模具厂设计的模具的变化,从错误中吸取教训。混凝土隔离墩模具生产不仅需要技术,更需要维护获悉,必须醒来后脱模模具清洗,以确保没有混凝土表面和污点,下次将使用剩余模具硬化表面不光滑的石头制成的水泥,影响使用。

Therefore, in order to improve the design level of the concrete pier mould, the following points should be done, first of all, understand each mould design details, understand each part of the mould; second, a similar design, in the design of Reference and understanding of other mold processing and production products, absorb experience and lessons; in addition to more understanding of the injection molding machine working process, deepen the mold; after understanding, processing and product process to know each process. BE AWARE OF MOLD design changes in the mold factory and learn from mistakes. The concrete isolation pier mold production not only needs technology, but also needs maintenance to know, must wake up after demoulding mold cleaning, in order to ensure that there is no concrete surface and stains, the next time will use the remaining mold to harden the surface of the non-smooth stone made of cement, affect the use.

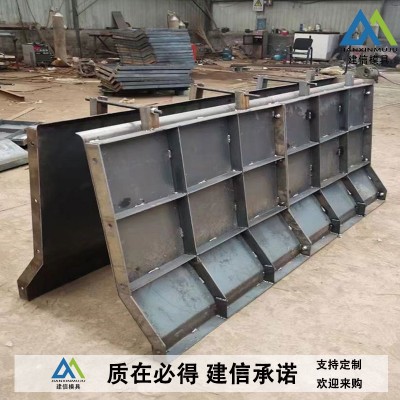

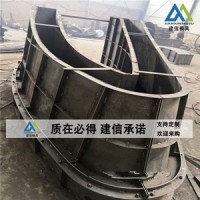

防撞护栏模具 公路防撞墙模具结构组

防撞护栏模具 公路防撞墙模具结构组

道路防撞墙钢模具的性能及养护介绍

道路防撞墙钢模具的性能及养护介绍

高速标志桩钢模具,标志桩塑料模具-

高速标志桩钢模具,标志桩塑料模具-

防撞墙钢模具,水泥防撞墙模具使用

防撞墙钢模具,水泥防撞墙模具使用

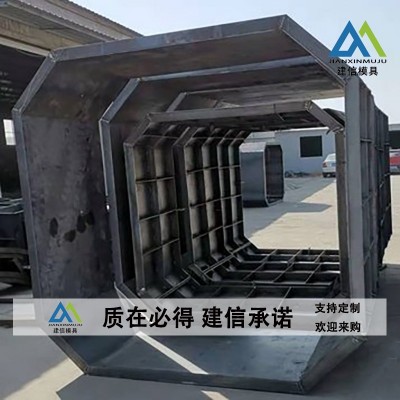

水泥检查井模具的具体了解与生产方

水泥检查井模具的具体了解与生产方

安全岛钢模具 —— 建信钢模具厂家

安全岛钢模具 —— 建信钢模具厂家

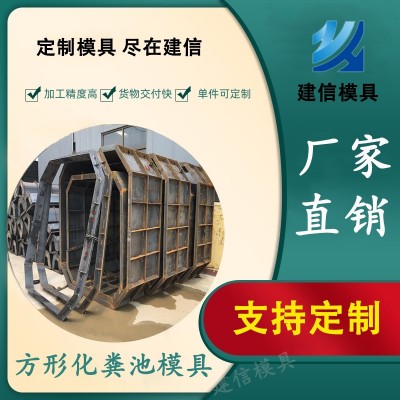

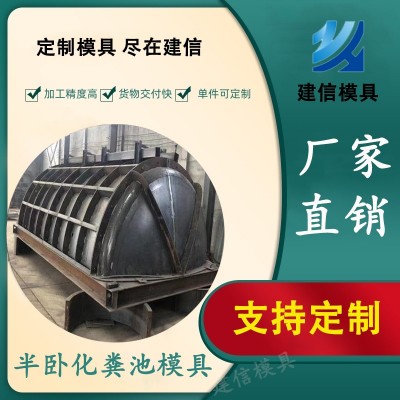

水泥化粪池模具的制作工艺 处理技术

水泥化粪池模具的制作工艺 处理技术

福建船型安全岛模具 水泥收费岛模具

福建船型安全岛模具 水泥收费岛模具

预制检查井钢模具产品型号,制作工

预制检查井钢模具产品型号,制作工

微信客服

微信客服