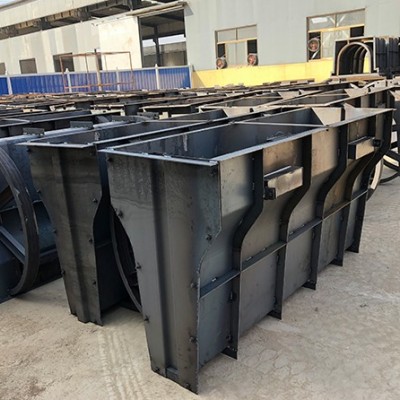

水泥流水槽钢模具经过长期使用过后就会产生各方面的磨损,所以要想延长寿命的话就要

定时维护模具,主要需要:主要工作零件的材料的问题,选材不当。材料性能不良,不耐磨;模

具钢未精炼, 具有大量的冶炼缺陷;凸凹模,锻坯改锻工艺不完善,遗存有热处理隐患。结构

设计问题,冲模结构不合理。细长凸模没有设计加固装置,出料口不畅现堆集,卸料力过大使

凸模承受交变载荷加剧等。水泥流水槽模具在使用中只要操作规范,按照组装模具、刷油

、灌浆、震动、晾晒、拆模的顺序来进行操作,很容易就可以生产出合格耐用固定流水槽

预制件,而且流水槽模具的拼装只需要将内模和外模间的螺栓拧上,震动后就可以等待其

自然晾晒了,工人在一个预制件的生产上花费的时间甚至不会超过5分钟,能够提高整个工

程的生产效率;在大小规格方面,此类模具的直径从50cm到80cm不等,产出的预制件有着

均匀的壁厚,受力均匀且有着较长的使用寿命,十分适合用于道路排水

The cement channel steel mold will be worn in all aspects after long-term use.

Therefore, in order to prolong the service life, it is necessary to regularly

maintain the mold. The main needs are: the material of main working parts and

improper material selection. Poor material performance and no wear resistance;

Die steel is not refined and has a large number of smelting defects; Punch and

die, forging blank changing forging process is not perfect, and there are

hidden dangers of heat treatment. Structural design problem, die structure is

unreasonable. The slender punch is not designed with a reinforcement device,

the discharge port is not smooth, and the stacking occurs. Excessive unloading

force aggravates the punch's bearing alternating load, etc. As long as the

operation of the cement chute mold is standardized and operated in the order of

assembling the mold, painting, grouting, vibration, drying and formwork

removal, it is easy to produce qualified and durable prefabricated parts of the

fixed chute. Moreover, the assembly of the chute mold only needs to screw the

bolts between the inner mold and the outer mold. After vibration, it can wait

for its natural drying, The time spent by workers on the production of a

prefabricated part will not even exceed 5 minutes, which can improve the

production efficiency of the whole project; In terms of size and specification,

the diameter of such molds ranges from 50cm to 80cm. The prefabricated parts

produced have uniform wall thickness, uniform stress and long service life,

which are very suitable for road drainage

水泥检查井模具的具体了解与生产方

水泥检查井模具的具体了解与生产方

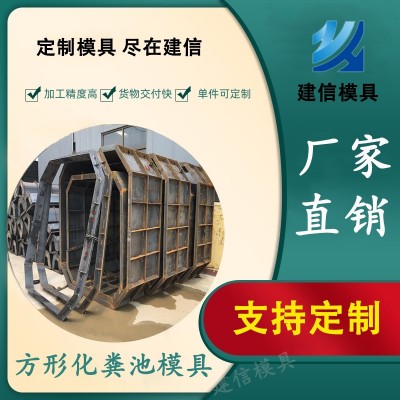

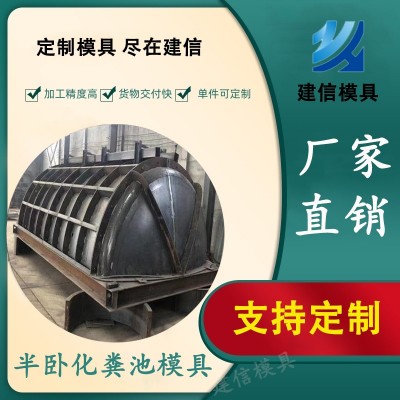

水泥化粪池模具的制作工艺 处理技术

水泥化粪池模具的制作工艺 处理技术

甘肃圆形检查井模具的加工以及施工

甘肃圆形检查井模具的加工以及施工

混凝土隔离带,隔离墩模具的生产说

混凝土隔离带,隔离墩模具的生产说

扭王字块钢模板详细介绍

扭王字块钢模板详细介绍

高速标志桩钢模具,标志桩塑料模具-

高速标志桩钢模具,标志桩塑料模具-

高速安全岛模具加工,预制生产收费

高速安全岛模具加工,预制生产收费

陕西圆形水泥检查井模具 水泥检查井

陕西圆形水泥检查井模具 水泥检查井

道路防撞墙钢模具的性能及养护介绍

道路防撞墙钢模具的性能及养护介绍

微信客服

微信客服