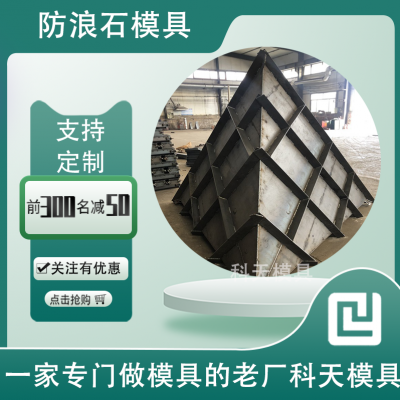

扭王字块模板-扭王字块钢模板-详细介绍是从模板的形状、尺寸等多方面进行详细的概括

,首先模板的形状,模板的形状不是固定的像进场在渤海等海边经常看到的四脚空心块、

扭工字块、扭王字块,都属于防浪石的一种,而扭王字块在防浪石预制件生产中数量非常

多,工程负责人可以根据自己的真实工程需求跟模板制作工厂进行沟通,制作出符合自己

工程标准的扭王字块模板,然后再使用模板制作扭王字块。

Accropode block Formwork - Accropode block steel formwork - detailed

introduction is a detailed summary from the shape, size and other aspects of

the formwork

Firstly, the shape of the formwork is not fixed, such as the four

legged hollow blocks often seen in the Bohai Sea

Twisted I-shaped block and

twisted King shaped block belong to a kind of wave proof stone, and the number

of twisted King shaped blocks is very large in the production of wave proof

stone prefabricated parts

In addition, the project leader can communicate with

the template making factory according to his real engineering needs to make a

template that meets his own needs

Project standard Accropode template, and then

use the template to make Accropode.

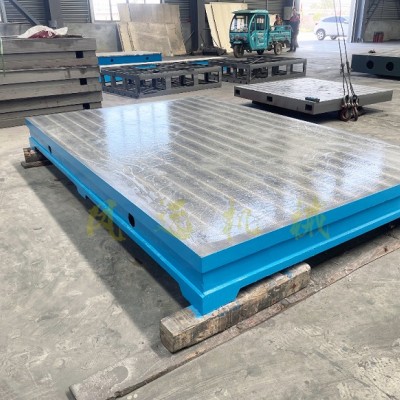

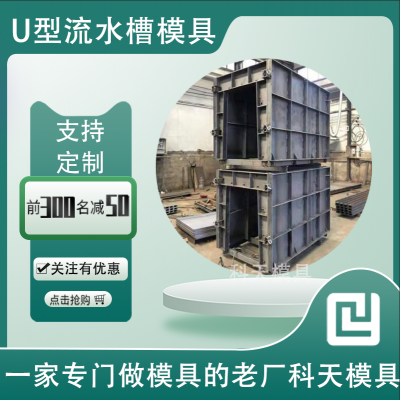

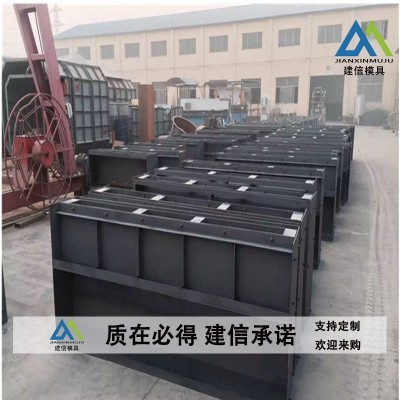

扭王字块模板-扭王字块钢模板的尺寸也不是固定的,尺寸一般都是按一套进行说明的,经

常会制作1.1米*1.1米或者2.5米*2.5米的或者1.8*1.8的2.3*2.3的具体的尺寸工程负责人

可以根据自己的真实工程需求进行生产,可以让专门的设计师设计出具体的设计图纸,然

后模板制作工厂的制作人员进行制作生产,但是在模板制作工厂的选择上一定要进行合理

的选择,可以进行多方面的对比,像工厂的切割钢板的技术、工厂制作出来的模板的质量

、模板的价格是否合理这几个方面进行详细的对比然后再进行选择,这样生产出来的模板

的使用寿命会非常的长久,制作出来的混凝土预制件的成型情况也会有着一定的保障。

Accropode Formwork - the dimensions of Accropode steel formwork are not fixed,

and the dimensions are generally described according to one set

Often make

specific dimensions of 1.1m * 1.1m or 2.5m * 2.5m or 1.8 * 1.8 and 2.3 * 2.3.

Project leader

It can be produced according to its own real engineering needs,

and special designers can design specific design drawings

After that, the

production personnel of the formwork production factory shall carry out the

production, but the selection of the formwork production factory must be

reasonable

The selection of can be compared in many aspects, such as the

technology of cutting steel plate in the factory and the quality of formwork

made by the factory

Whether the price of the template is reasonable or not is

compared in detail, and then selected to produce the template

The service life

of the concrete will be very long, and the molding of the fabricated concrete

precast parts will also have a certain guarantee.

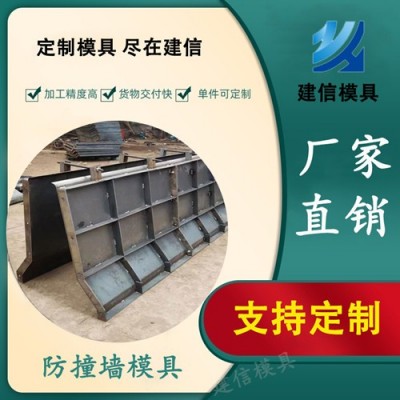

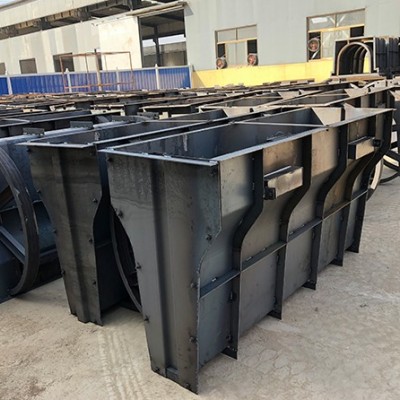

防撞护栏模具 高速防撞护栏模具 防

防撞护栏模具 高速防撞护栏模具 防

道路防撞墙钢模具的性能及养护介绍

道路防撞墙钢模具的性能及养护介绍

混凝土隔离带,隔离墩模具的生产说

混凝土隔离带,隔离墩模具的生产说

高速安全岛模具加工,预制生产收费

高速安全岛模具加工,预制生产收费

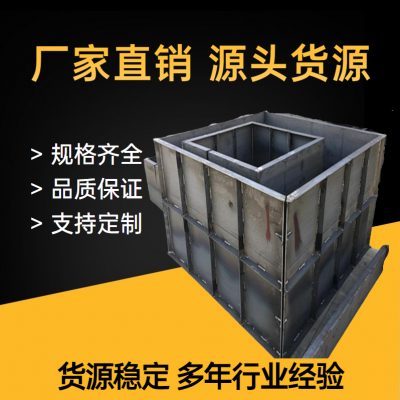

预制方井钢模具 水泥方井模具-建信

预制方井钢模具 水泥方井模具-建信

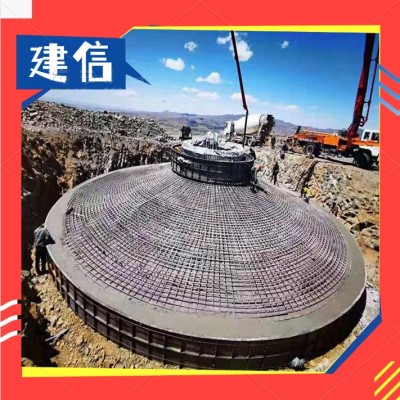

现浇风电基础底座钢模具 风力发电基

现浇风电基础底座钢模具 风力发电基

箱型砌块钢模具混凝土的分类介绍-建

箱型砌块钢模具混凝土的分类介绍-建

防撞墙钢模具,水泥防撞墙模具使用

防撞墙钢模具,水泥防撞墙模具使用

防撞墙模具-现浇防撞墙钢模具加工厂

防撞墙模具-现浇防撞墙钢模具加工厂

优质六角护坡模具,水泥六角护坡模

优质六角护坡模具,水泥六角护坡模

微信客服

微信客服