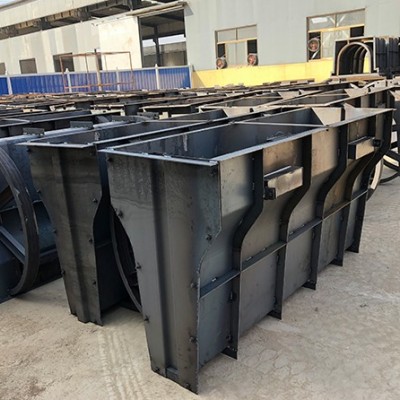

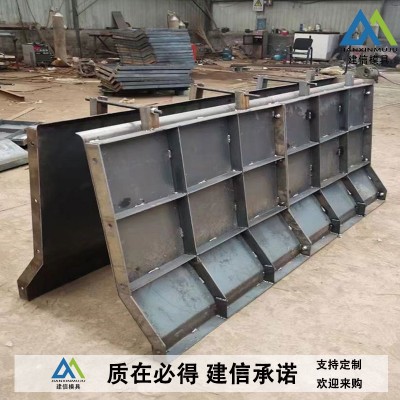

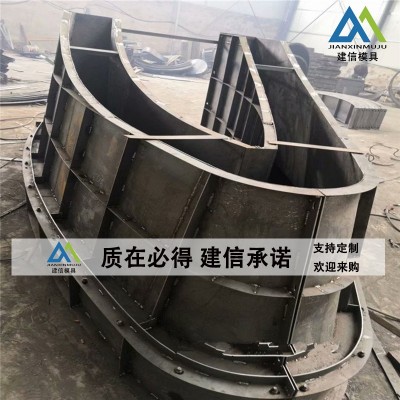

安全岛模具主要是应用在我们的高速工程的建设当中,通过该模具生产出来的收费岛用于我们的高速

路口当中,该模具整体使用起来比较方便,生产出来的混凝土制块成型效果非常的好,呈现一个帆状

,样式比较独特。该模具整体生产比较简单,样式没有太多的变化,规格变化可以根据客户的设计图

纸来进行定制。The Safe Island mould is mainly used in the construction of our high-speed

projects. The Toll Island produced by the mould is used in our high-speed intersections.

The overall use of the mould is relatively convenient, the production of concrete block

molding effect is very good, showing a sail-shaped, more unique style. The overall

production of the mold is relatively simple, not too many changes in style,

specifications can be customized according to the customer’s design drawings.

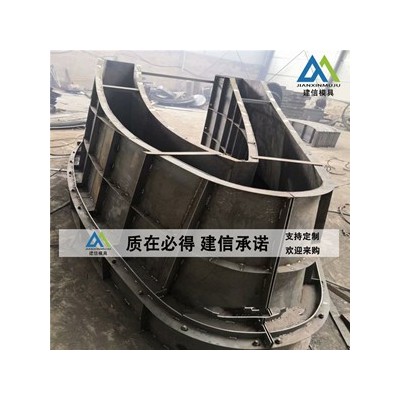

安全岛模具是一种组合式的钢模具,既可以采用现场浇筑的生产方式,也可以采用预制生产的方式来

进行收费岛的生产。安全岛模具顶端为一个锥形,能够很好的起到防撞的作用,在车辆撞上收费岛的

时候能够起到较好的缓冲作用,使车辆的速度降下来,并且模具尖端的这个设计也可以使收费站上的

人和驾驶人员更好的观察到对方,使前方的视野更加开阔。模具一般还会分为岛头以及岛尾两个部分

,在生产的时候需要进行进行组装使用,比对好安装的位置之后进行混凝土的浇筑就行,并对其进行

振捣,使内部的浆料充分的凝结在一起,密度增大形成比较完美的混凝土制块就完成生产任务了。

The mode of production is a modular steel mold that can be either cast on site or

fabricated to produce a toll island. The top of the safety island mould is a cone, which

can play a good role in preventing collision, and can play a better buffer role when the

vehicle hits the toll island, so that the speed of the vehicle will be reduced, and the

cutting edge of the mold design can also make the toll station and the driver better

observe each other, so that the front of the field of vision more open. The mould is

usually divided into two parts: the head of the island and the tail of the island. When

the mould is manufactured, it needs to be assembled and used. After comparing the

position of the installation, the concrete can be poured and the mould can be vibrated,

so that the internal slurry fully condensed together, the density increases to form a

more perfect concrete block on the completion of the production task

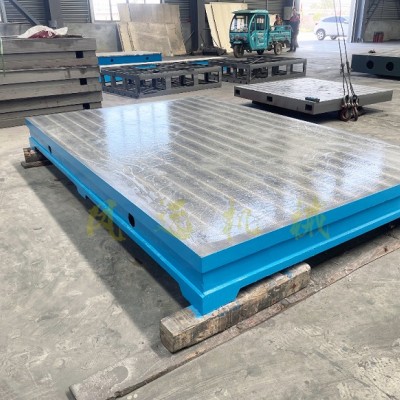

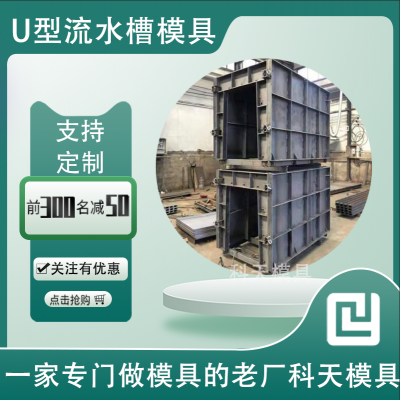

安全岛模具制作工艺:安全岛模具是根据目前高速公路进出口使用的岛头、岛尾以及中间的基础部分

进行的模具生产,收费岛钢模具的生产一般都是采取现浇的生产作业方式,这样可以较少二次搬运的

成本。

SAFE ISLAND MOLD MANUFACTURING PROCESS: Safe Island mold is based on the current import

and export use of the island head, island tail and the middle of the base part of the

mold production, the charging island steel mold production is generally to take the

cast-in-place mode of production operations, so that the cost of secondary handling can

be reduced.

混凝土隔离带,隔离墩模具的生产说

混凝土隔离带,隔离墩模具的生产说

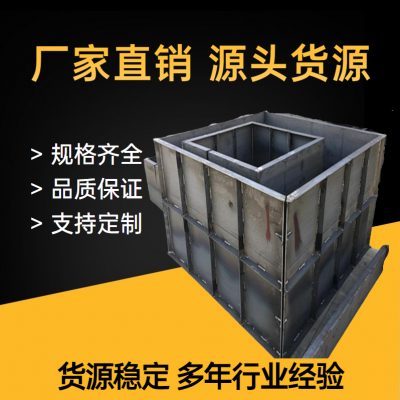

箱型砌块钢模具混凝土的分类介绍-建

箱型砌块钢模具混凝土的分类介绍-建

高速标志桩钢模具,标志桩塑料模具-

高速标志桩钢模具,标志桩塑料模具-

高速收费模具 环形岛模具-建信专业

高速收费模具 环形岛模具-建信专业

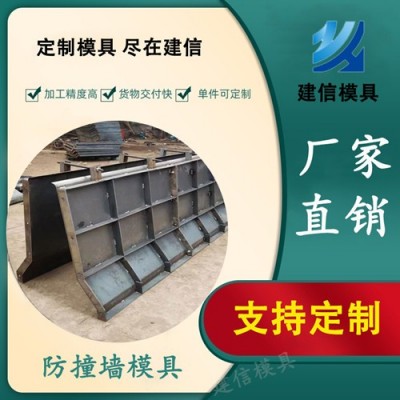

防撞护栏模具 公路防撞墙模具结构组

防撞护栏模具 公路防撞墙模具结构组

安全岛钢模具 —— 建信钢模具厂家

安全岛钢模具 —— 建信钢模具厂家

预制方井钢模具 水泥方井模具-建信

预制方井钢模具 水泥方井模具-建信

防撞护栏模具 高速防撞护栏模具 防

防撞护栏模具 高速防撞护栏模具 防

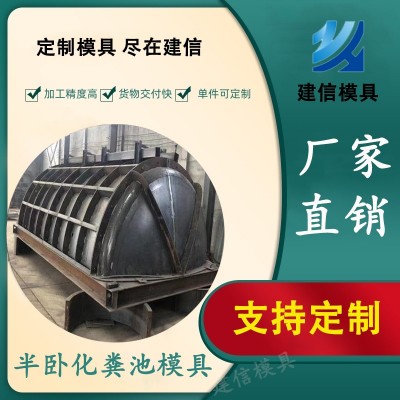

水泥化粪池模具的制作工艺 处理技术

水泥化粪池模具的制作工艺 处理技术

微信客服

微信客服