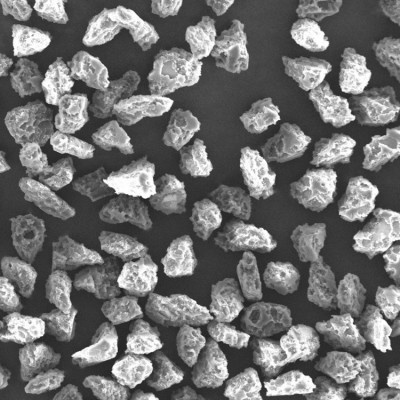

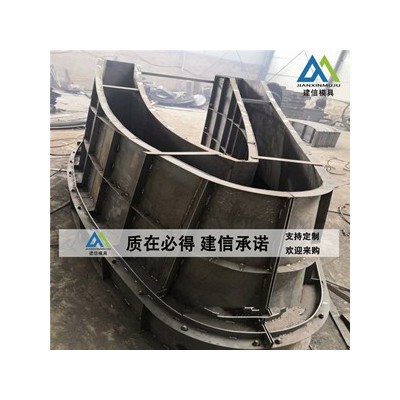

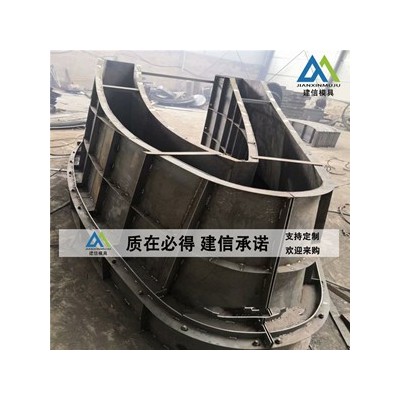

防撞墙模具主要是以纯原包料的聚丙烯颗粒和一些耐磨材质调配而成的塑料模具,具有较高的成型面

和实际使用的便利价值,该模具也可以叫做钢模具,它也是道路使用中的一种,按照尺寸可以划分出

几百种不同型号的模具,每一种尺寸型号的改变都是和工程使用互相对立的,专用性特别强,采取塑

料材质来生产水泥砖,是提高整体层次的保证。

The anti-collision wall mould is mainly a plastic mould which is made up of pure raw

polypropylene particles and some wear-resistant materials. It has high forming surface

and convenient value in actual use. The mould can also be called steel mould, it is also

a kind of road use, according to the size can be divided into hundreds of different

models of mold, each size type of change is opposite to the use of the project, the

specificity is particularly strong, using plastic materials to produce cement bricks, is

a guarantee to raise the level of the whole.

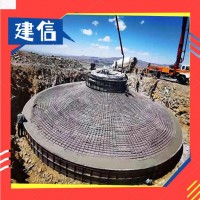

高速公路防撞墙模具大样图按照高速公路的里程标准设计,有的把高速公路防撞墙模具叫做新泽西护

栏模具,按照防撞墙模具的生产标准计算,每成型一块高速公路防撞墙就要等待15个小时以上,才能

达到混凝土完全晒干的情况。

Highway crash wall mold large sample design in accordance with highway mileage standards,

some highway crash wall mold called Jersey barrier, in accordance with the production

standards of crash wall mold calculation, each block of highway crash wall will have to

wait more than 15 hours, to achieve complete drying of concrete

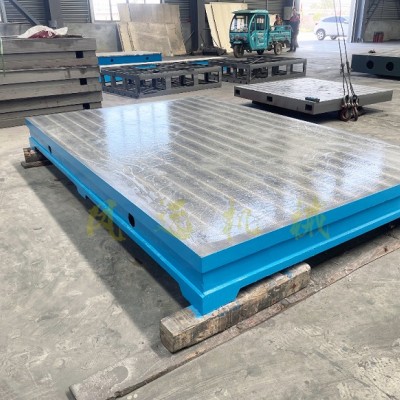

防撞墙钢模具不断改进生产技术,使先进的制造精细潜力,展现出独特的魅力的设备,并带领人民去拥抱

美好生活的高品质,时尚的成功之路,在各行业的应用,以帮助用户寻找未来的成功之路很宽的范围内,

绿色的生活环境.防撞墙钢模具以进一步改进的技术,创新的品牌选择的项目的独特的生产性能,深受广

大用户的关注和欢迎.我国防撞墙钢模具的设计和制造水平有了很大提高。作为技术型企业,提高模具

硬度、耐磨性,延长防撞墙模具的使用周期,让模具具有较强的擦伤能力和更高的生产效率。

The anti-collision Wall Steel Mold continuously improves the production technology,

enables the advanced manufacture fine potential, displays the unique charm the equipment,

and leads the people to embrace the happy life the high quality, the fashionable success

road, in each profession application, to help users find their way to future success

within a wide range of green living environment. The anti-collision wall steel die with

further improved technology, innovative brand selection of the project’s unique

production performance, by the majority of users attention and welcome. The level of

design and manufacture of steel mould for crashworthiness wall has been greatly improved

in China. As a technical enterprise, it can improve the hardness and wear resistance of

the mould, prolong the service life of the mould, and make the mould have stronger

scratch ability and higher production efficiency.

道路防撞墙钢模具的性能及养护介绍

道路防撞墙钢模具的性能及养护介绍

优质六角护坡模具,水泥六角护坡模

优质六角护坡模具,水泥六角护坡模

防撞墙钢模具,水泥防撞墙模具使用

防撞墙钢模具,水泥防撞墙模具使用

安徽水泥安全岛模具 高速收费岛模具

安徽水泥安全岛模具 高速收费岛模具

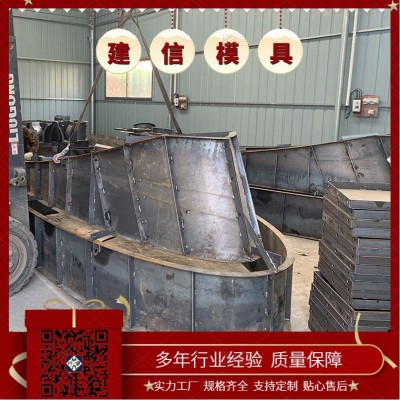

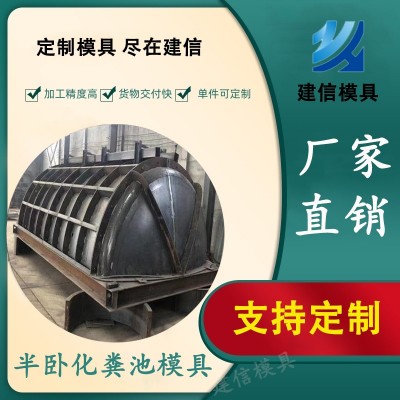

水泥化粪池模具的制作工艺 处理技术

水泥化粪池模具的制作工艺 处理技术

混凝土安全岛模具 现浇收费岛模具

混凝土安全岛模具 现浇收费岛模具

高速收费模具 环形岛模具-建信专业

高速收费模具 环形岛模具-建信专业

混凝土隔离墩模具生产过程介绍-建信

混凝土隔离墩模具生产过程介绍-建信

甘肃圆形检查井模具的加工以及施工

甘肃圆形检查井模具的加工以及施工

混凝土流水槽模具 流水槽模具的特点

混凝土流水槽模具 流水槽模具的特点

微信客服

微信客服