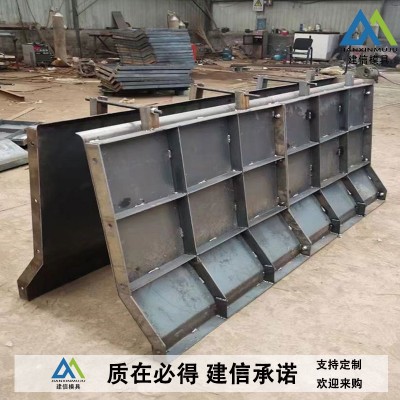

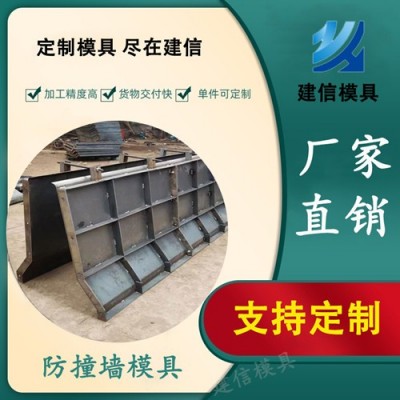

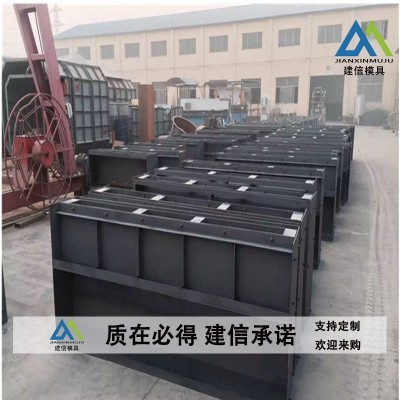

防撞护栏模具,公路防撞墙模具采用的是分体结构组装的形式,按照对混凝土护栏的

设计标准,大部分是以上下、左右连接为主的。防撞护栏模具,公路防撞墙模具生产

方式是现场浇注,而且为了保证生产出来产品体型一致,在道路上建设的时候非常的

美观,所以我们在购买模具的时候就要注意模具必须具有高一致性的特点,这样在生

产的时候才能保证规模化的生产,保证美观。防撞护栏模具,公路防撞墙模具的使用

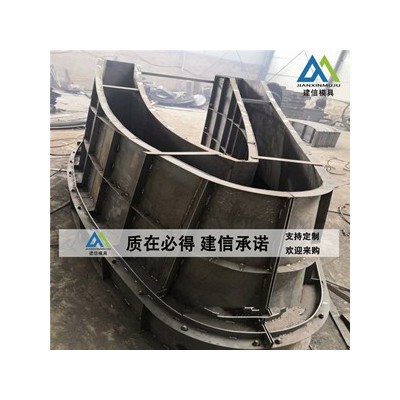

方法是按照设计图纸要求定制的,采用的主体形式是按照路边防撞护栏以及中央防撞

护栏两种制作形式,一般情况下中央防撞护栏钢模板定制的少一些,路边定制的多一

些,两者在外形上存在的区别就是,路边护栏有一块直板,而中央护栏全部是斜板的

形式出现,而且很多公路上要求顶部设置工装,或者其他设施。防撞护栏模具,公路

防撞墙模具的制作要求,一般都是与每米为单位

The anti-collision barrier mold and the highway anti-collision wall mold

adopt the form of split structure assembly. According to the design

standard of concrete barrier, mosIt is mainly connected up, down, left

and right. The production mode of anti-collision barrier mold and highway

anti-collision wall mold is on-site pouring, and in order to ensure

production

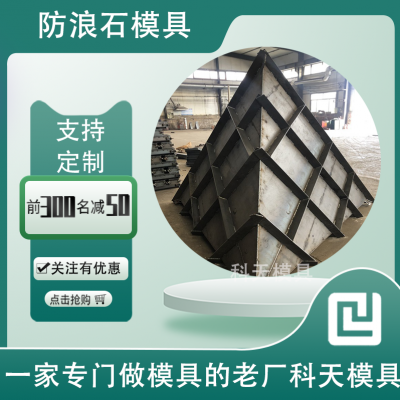

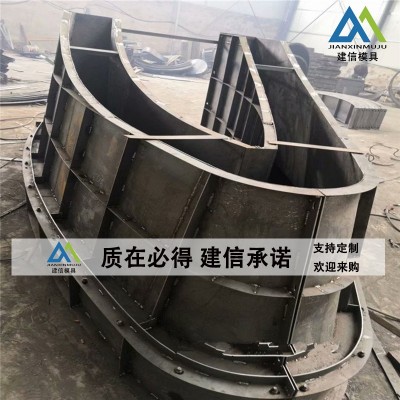

防撞护栏模具,公路防撞墙模具设计理念是以方便使用、重复利用为主要出发点,防

撞墙模具,公路防撞墙模具设计理念一般都是现浇生产制作,有人就会很疑惑,预制

生产有那么多的好处,为什么不进行预制件的生产制作,因为混凝土防撞墙钢模具生

产出来的防撞墙为了更好的防撞效果,需要牢牢的贴紧地面,这样才受到撞击的时候

才不会容易倒,所以防撞墙模具,公路防撞墙模具通过现场组装,然后进行混凝土的

浇筑。防撞护栏模具,公路防撞墙模具的体型非常大,生产出来的混凝土产品重量一

定会很大,所以在运输的时候是有一定的困难的,如果我们单单是对模板进行运输就

会好很多,因为模具虽然体型大,但是是可以进行拆分的,这样我们就可以将模具拆

分开来,然后在车辆上进行摞放放置,这样可以有效的节省空间。

The design concept of anti-collision barrier mold and highway anti-collision wall mold is based convenience and reuseThe design concept of wall striking mould is generally cast-in-situproduction. Some people will wonder why prefabrication production has so many benefits. Why notFor the production of prefabricated parts, the anti-collision wall produced by the

steel mold of concrete anti-collision wall needs to be firmly fixed for better anti-collision effectClose to the ground so that it will not fall easily when impacted, so the anti-collision wall mold and highway anti-collision wall mold are assembled on site

Concrete pouring shall be carried out after. The anti-collision barrier mold and the highway anti-collision wall mold are very large, and the weight of the concrete products produced is certain

It will be very big, so it will be difficult to transport. If we only transport the formwork, it will be much better, because the formwork

Although the tool is large, it can be disassembled so that we can separate the mold and stack it on the vehicleThis can effectively save space.

高速安全岛模具加工,预制生产收费

高速安全岛模具加工,预制生产收费

防撞护栏模具 高速防撞护栏模具 防

防撞护栏模具 高速防撞护栏模具 防

安全岛钢模具 —— 建信钢模具厂家

安全岛钢模具 —— 建信钢模具厂家

混凝土隔离墩模具生产过程介绍-建信

混凝土隔离墩模具生产过程介绍-建信

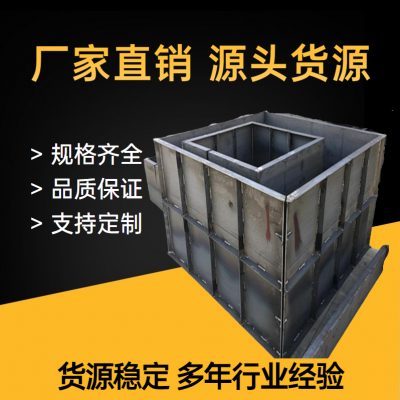

预制方井钢模具 水泥方井模具-建信

预制方井钢模具 水泥方井模具-建信

混凝土隔离带,隔离墩模具的生产说

混凝土隔离带,隔离墩模具的生产说

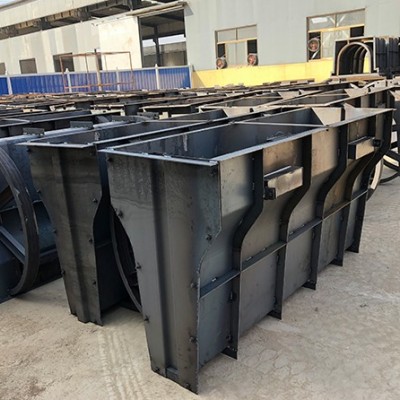

防撞墙模具-现浇防撞墙钢模具加工厂

防撞墙模具-现浇防撞墙钢模具加工厂

混凝土安全岛模具 现浇收费岛模具

混凝土安全岛模具 现浇收费岛模具

微信客服

微信客服